It’s All About Structural Design and Construction

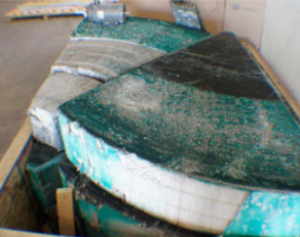

Severely Damaged Competitor Media

Poorly designed rims, spokes, and seals quickly wear under the stress of today’s ventilation demands. Many wheels fail in as little as 3 to 5 years – due to wheel deflection and media fatigue. This results in media separation, de-lamination, air contamination – high energy costs – and the need for complete wheel replacement.

Thermowheel TR Is The Replacement Energy Recovery Wheel of Choice

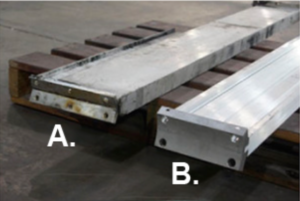

A. Competitor’s inferior spoke causes wheel deflection

B. Thermowheel rugged spoke design

Preferred by facilities owners and managers to correct the problem – and prevent it from happening again! Proven in hundreds of retrofit installations since 1985 – with ZERO failures. See the Thermowheel difference below:

Notice in the picture to the right that the competitor’s inferior spoke design “A” leads to wheel deflection over time, while Thermowheel’s rugged spoke design “B” will not.

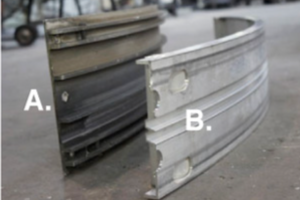

A. Competitor’s rim wears quickly

B. Thermowheel rim holds media secure

minimum 25 years

Here is another great illustration of competitor failure issues, Notice the picture on the left that the competitor’s rim wears down due to heat and overall bad design “A”, this leads to media shifting in the wheel. Thermowheel’s rim is more substantial and does not wear down. This keeps the media exactly where it needs to be with no failures for up to 25 years!